Structure

High-tech design engineering, quality-controlled factory construction, and highspeed onsite assembly deliver high-performance, sustainable buildings.

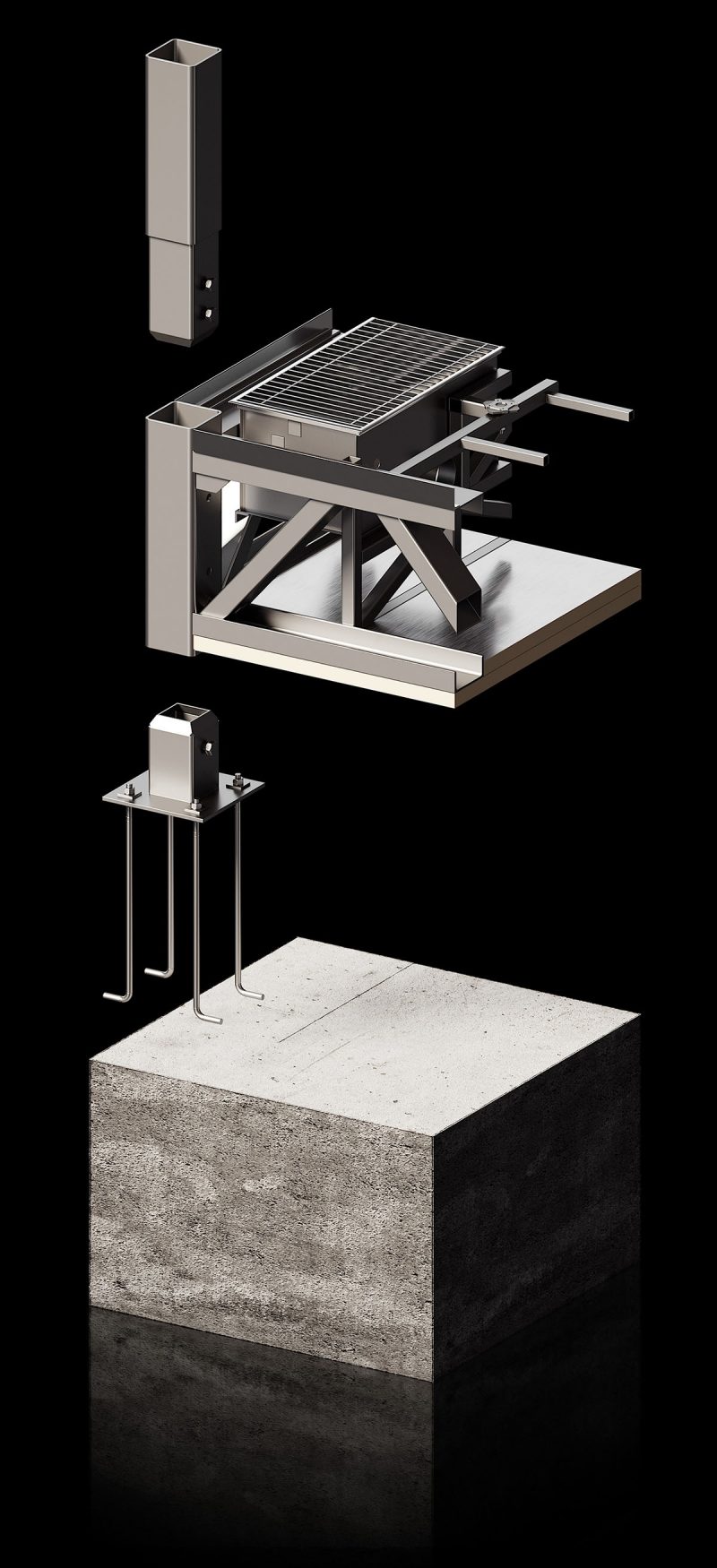

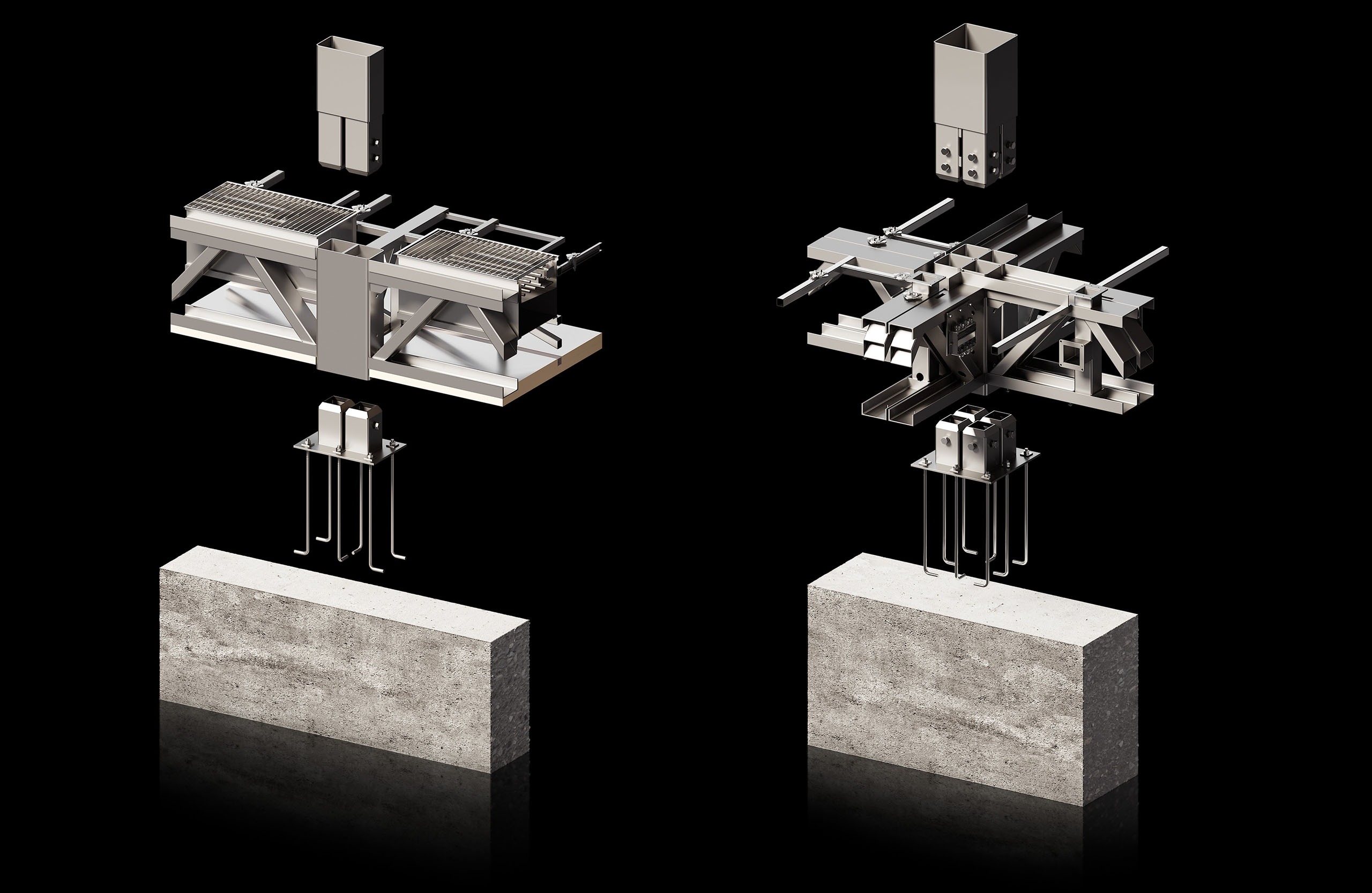

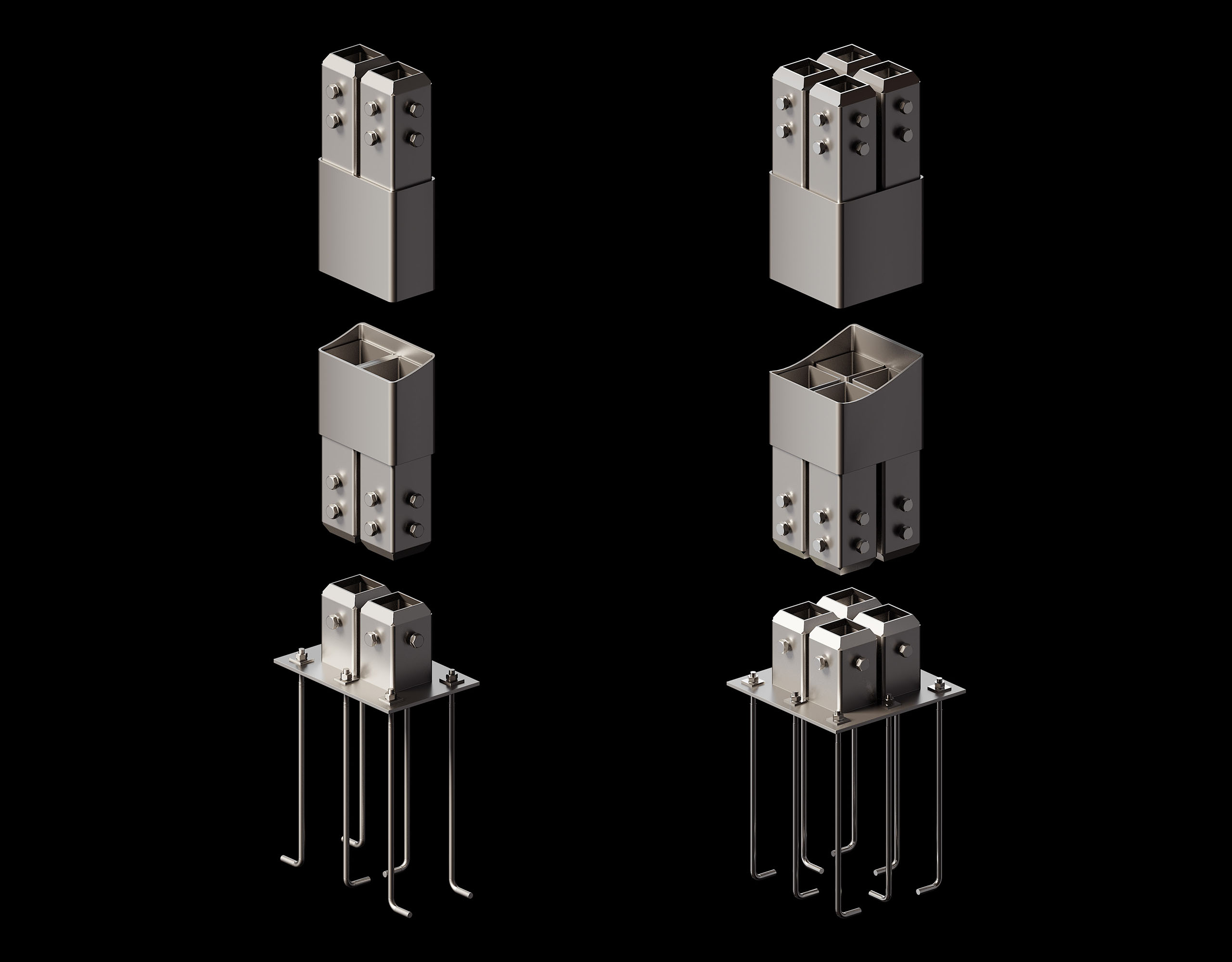

Foundation Anchor-locks

Precise placement of the foundation anchor-locks in the concrete foundation ensures a fearless bond between the earth and the structure. The factory-built floor units, which house the utility and automation systems, lock into the foundation anchor-locks, followed by the columns.

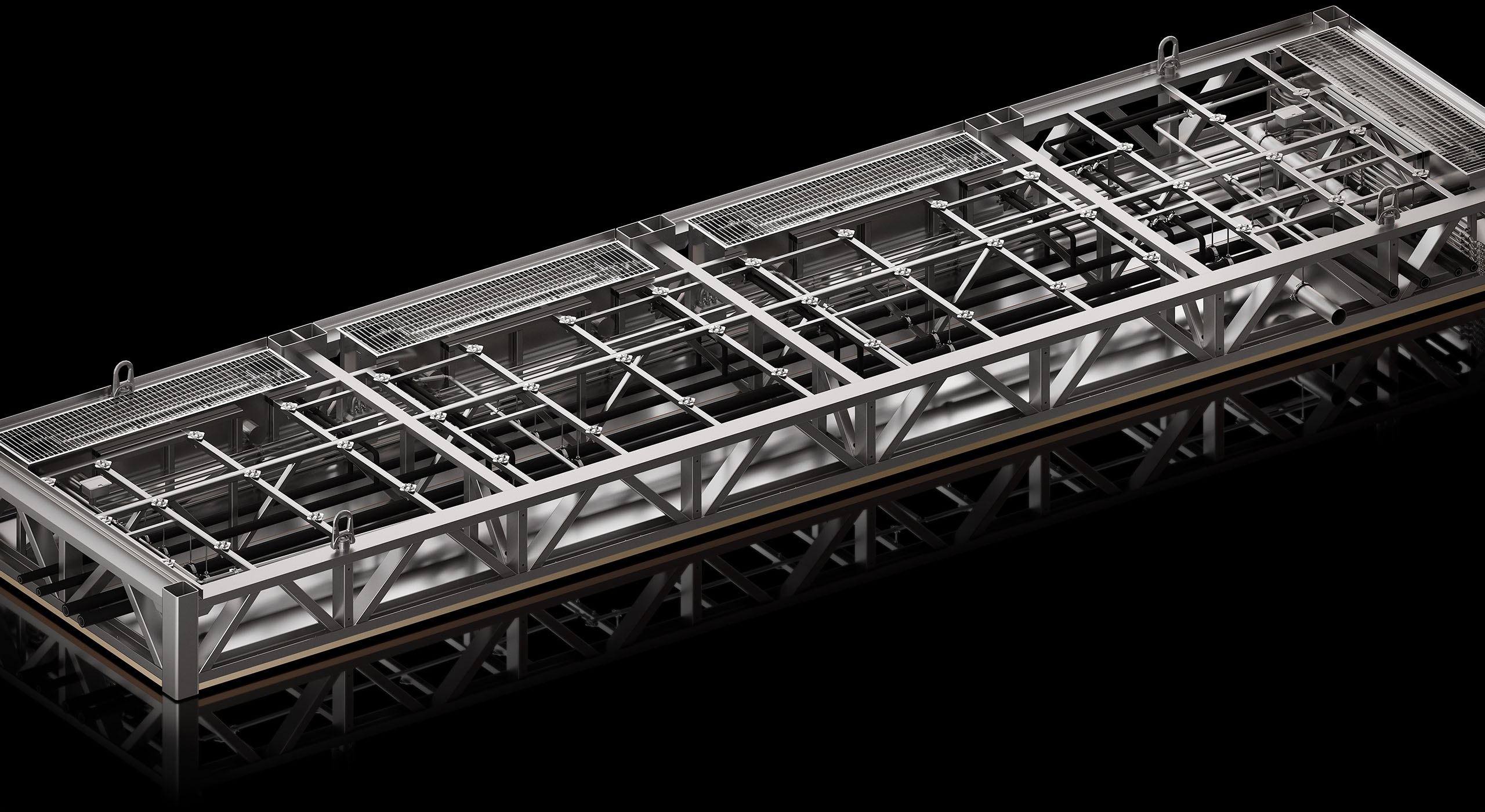

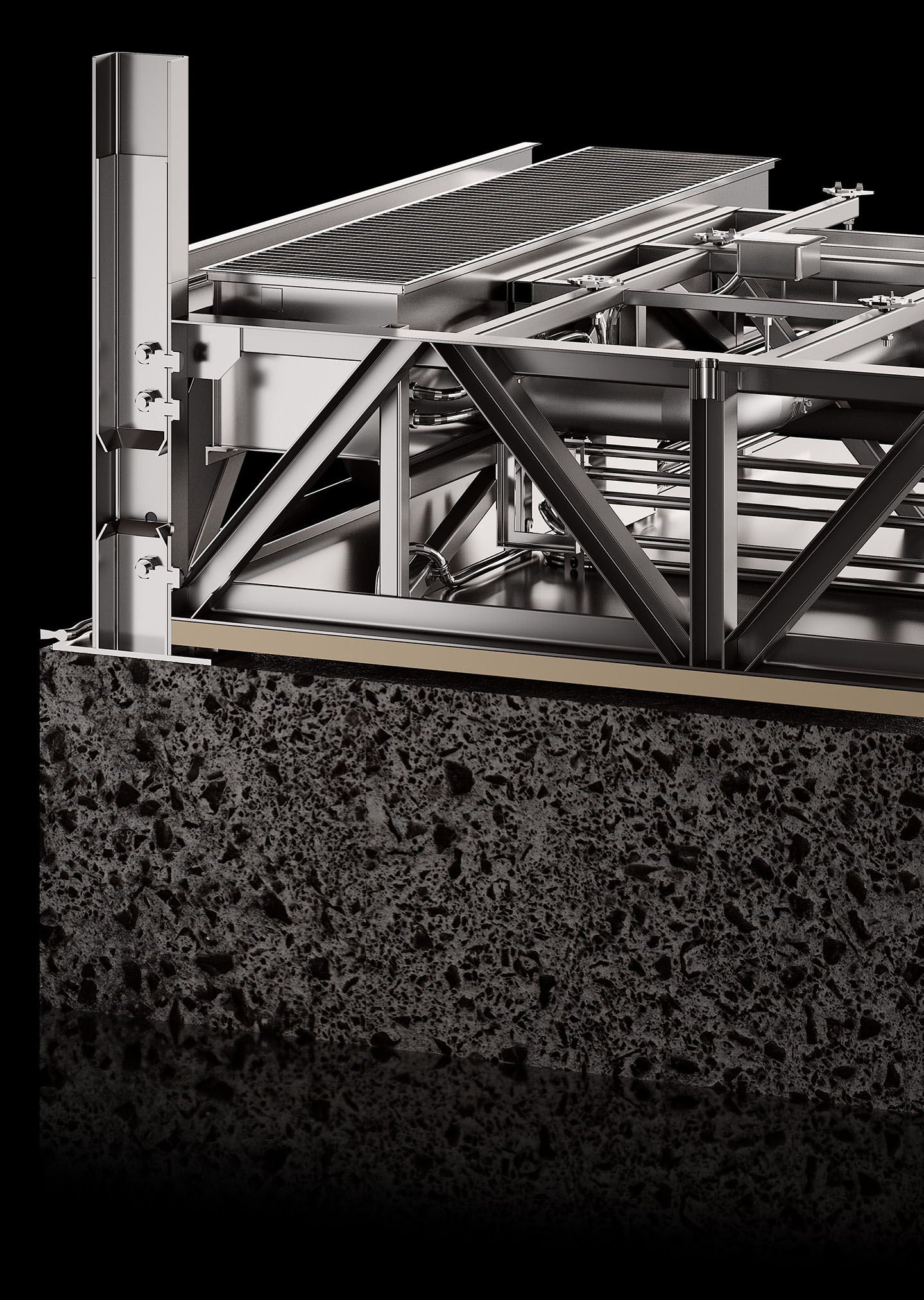

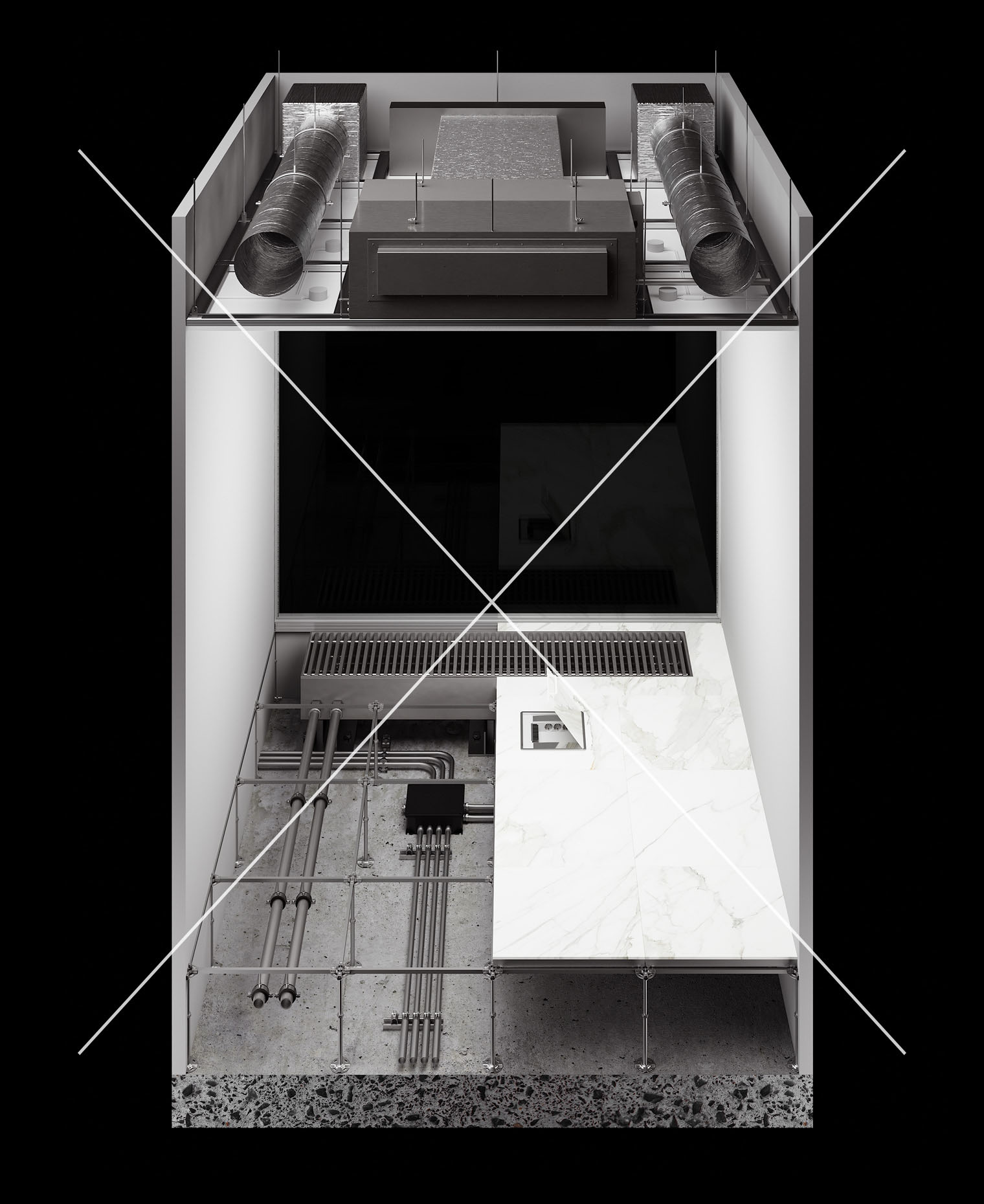

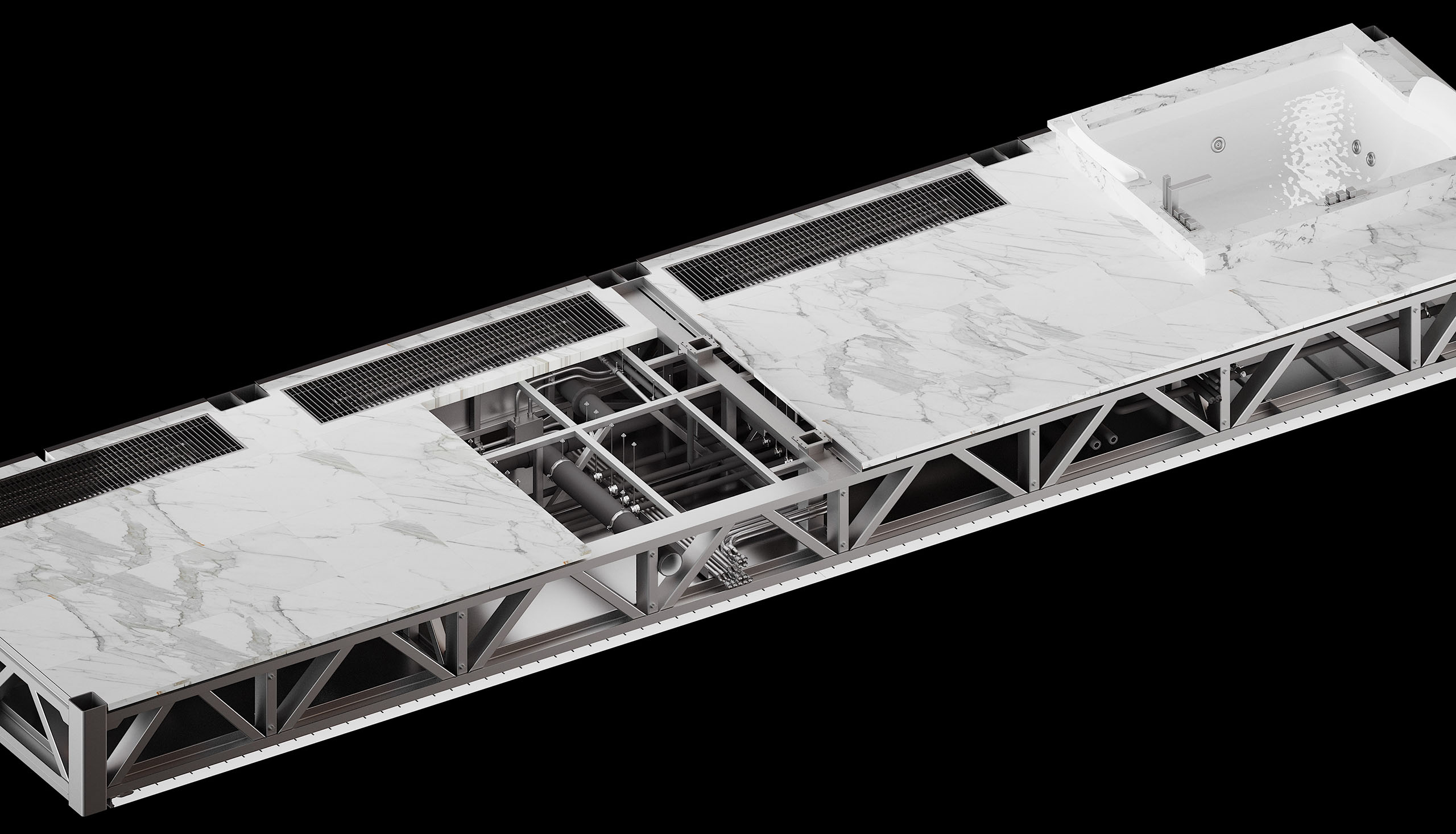

Floor Unit

Cables, pipes, ductwork, water storage tanks, and functional components for the automation, electrical, plumbing, and HVAC systems are engineered and built into the floor unit. Each design allows for flexibility of concept and customization without compromising other systems’ efficiency or disturbing the living space.

The floor units are factory direct, finished, and ready to connect to the foundation anchor-locks.

Catchers position and connect the floor units and support columns, and the floor units serve as the ground floor. Additional floor units are adapted for functionality and added to build more levels.

Flooring System

The accessible flooring system uses raised floor technology. The pedestal bases for each floor tile are factory-installed inside the steel floor panels, eliminating the need to glue each pedestal.

The hybrid panels are custom manufactured to meet the individual needs and design of each project. They arrive ready for easy installation and allow for accessibility to all underfloor systems.

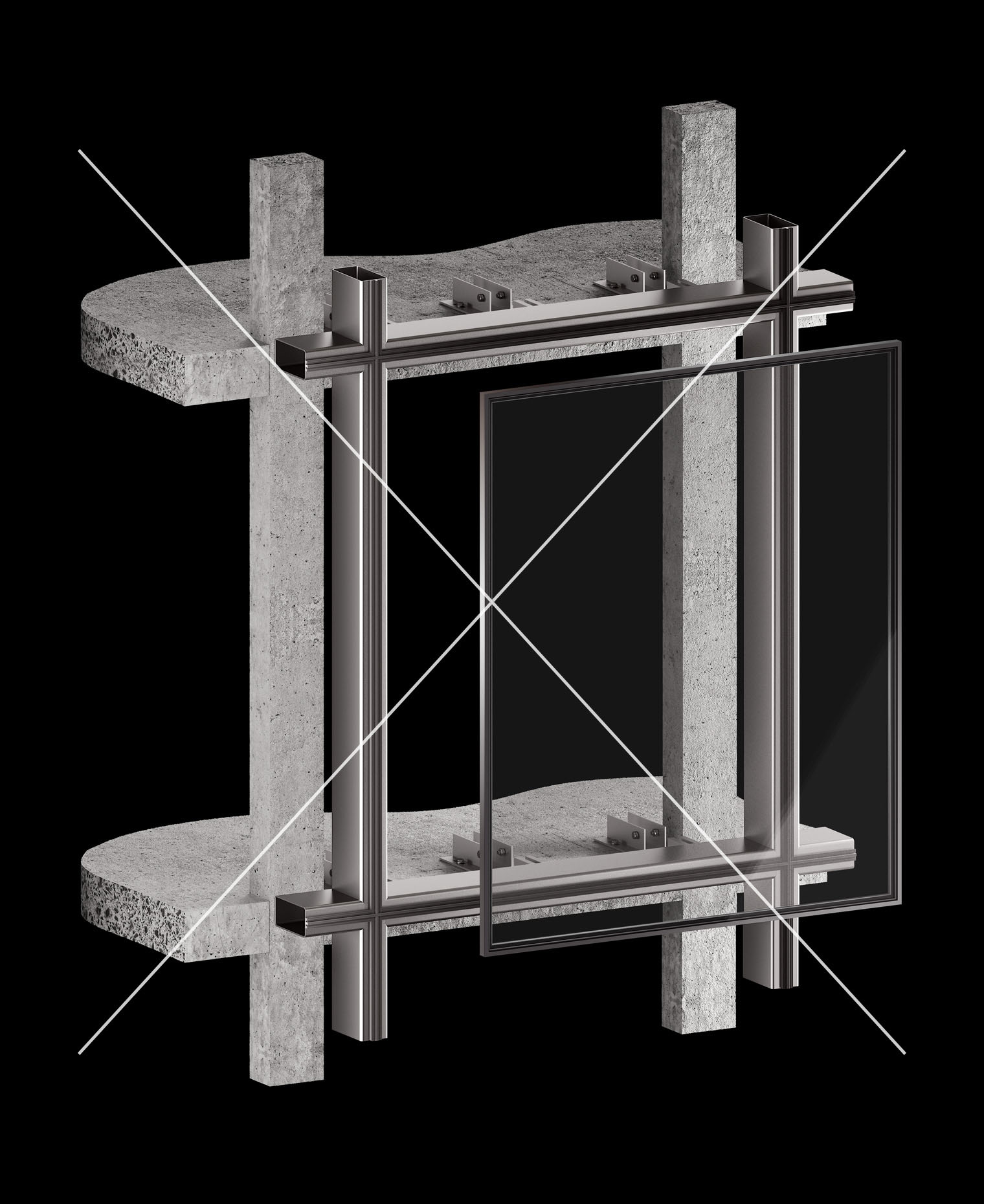

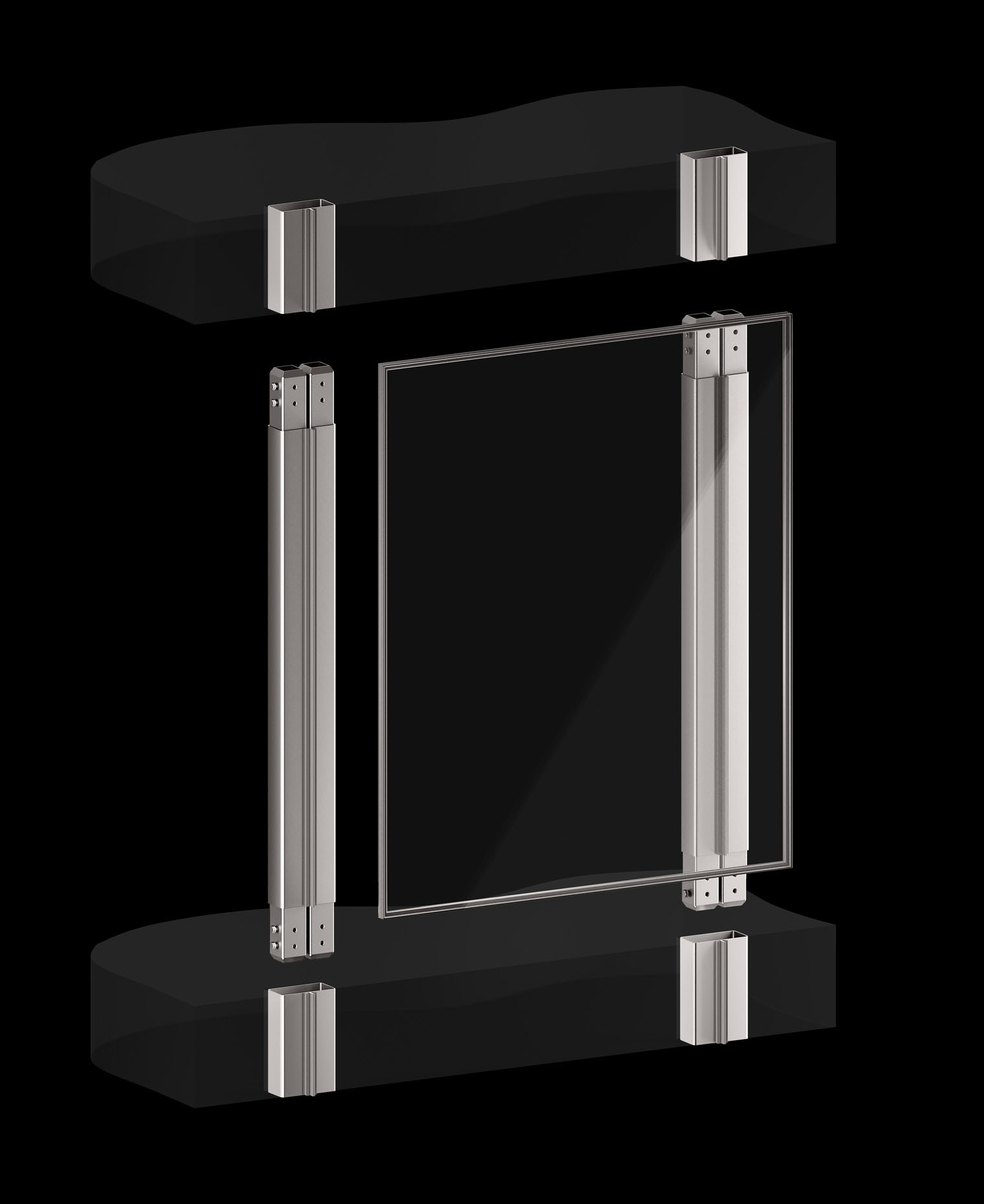

Column

High-speed assembly saves time and resources. The interlocking column system, built-in curtain wall system, energy-efficient windows, and facade are factory-built, quality-tested, and ready to assemble. Fast green construction and assembly of sustainable buildings reduce the environmental impact and CO2 emissions.

Long construction times are required to build concrete columns, assemble the curtain wall support structure, and install the glazing and facade cladding.

Fast green assembly with the 4 in 1 interlocking column system saves time and reduces construction waste. The column, built-in curtain wall system, energy-efficient windows, and facade are ready to assemble on delivery.

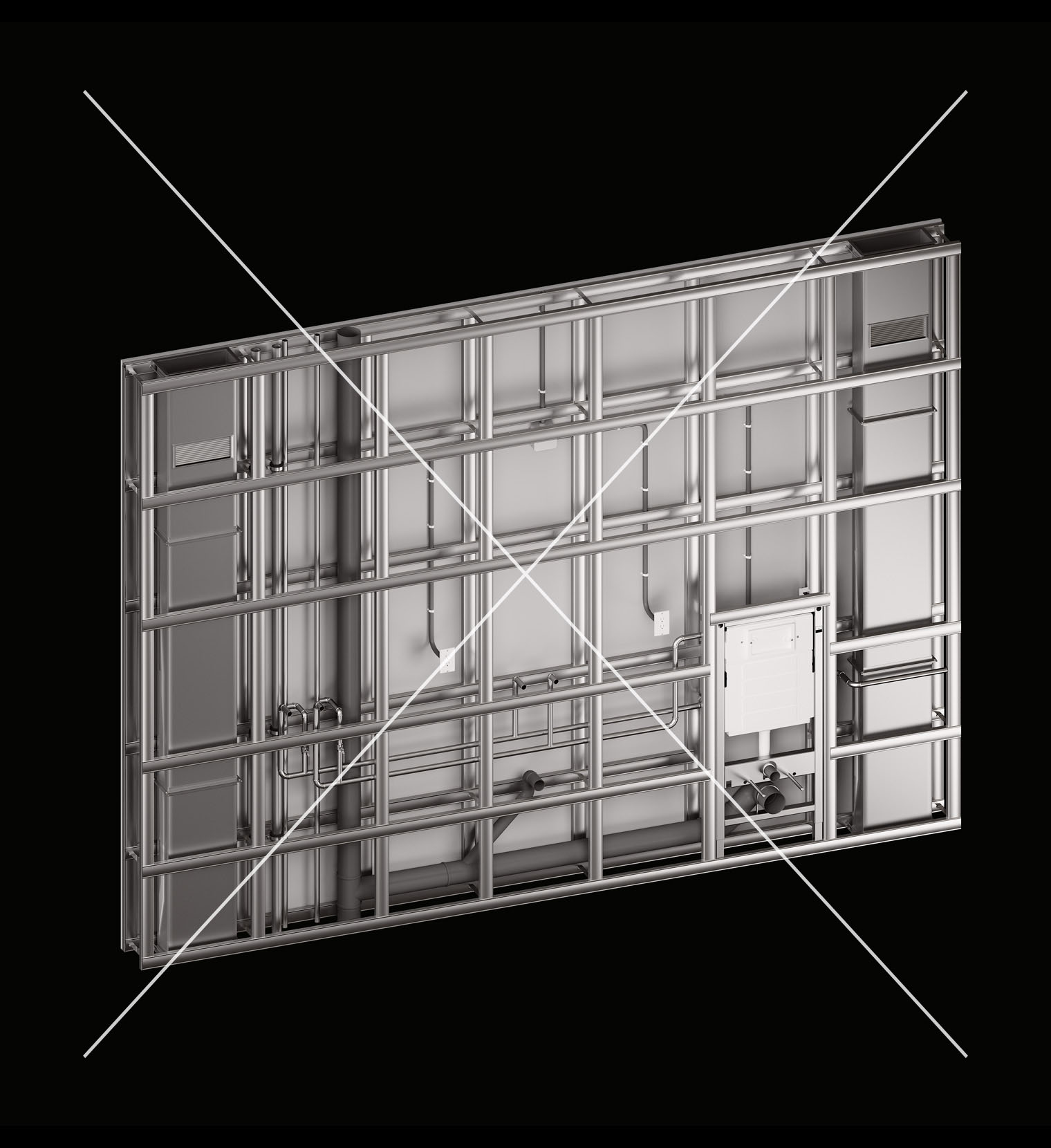

Interfloor Unit

This marvel of craftsmanship and design intricately weaves vital engineering systems together beneath every floor on each level. The ultra-thin lighting is built-in to the unit to save ceiling space, and the electrical, plumbing, HVAC, and automation systems are factory-installed and ready to use.

Outdated technology like underfloor convectors and ceiling fan coils are impractical, irrationally placed, and have limited accessibility.

Ceiling space is lost to engineering systems, ventilation ducts, ceiling fan coils, ceiling diffusers, grilles, and light fixtures that take up about 500 mm of valuable space. Slow construction and quality concerns are consequences of disjointed systems and methods, and onsite construction has limited quality assurance.

The inter-floor unit channels the engineering systems for fresh, disinfected, and humidified air, the water condensation system, the AK Airplex, the smart home automation system, and plumbing. The ultra-thin ceiling is only 50 mm thick since the other systems are located inside the floor unit and not the ceiling. Fast, sustainable factory-built construction integrates the electricity, automation, plumbing, and HVAC engineering inside the floor unit. All systems are ready for use on delivery.

Solid Wall

The wall block is made of Cross-Laminated Timber (CLT), a light sustainable building material. The steel core reinforces the wall strength, and the adjustable connectors allow for sections of walls to be disassembled for transport.

Outdated drywall construction with electrical, plumbing, and ventilation systems frequently need to be demolished for maintenance and require repairs for holes, mold, and cracks.

Unsustainable drywall cannot be reused or recycled—decomposing drywall leeches sulfate and other unhealthy chemicals into the water and releases hydrogen sulfide gas.

Solid engineered walls are sustainable and provide sound insulation equal to a 1m brick wall. All utilities run through the floor unit and allow easy access for maintenance.

Eco-friendly, custom-built bamboo, CLT walls and aluminum-honeycomb walls preserve air quality and the environment. Only natural materials are used, eliminating paint and volatile chemicals.

Place your reservation